Variable Compression Ratio Engines: Redefining Efficiency

The automotive world is on the cusp of a revolutionary breakthrough in engine technology that promises to redefine the boundaries of fuel efficiency and performance. Variable compression ratio engines, a concept that has tantalized engineers for decades, are finally becoming a reality. This groundbreaking technology has the potential to transform the way we think about internal combustion engines, offering a level of adaptability and efficiency previously thought impossible.

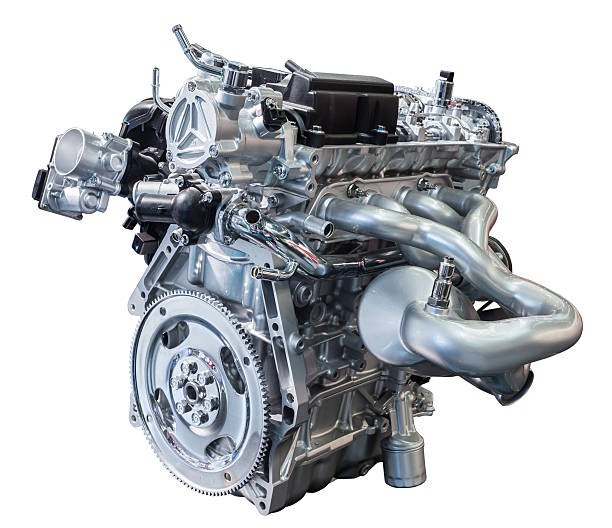

Traditional engines operate with a fixed compression ratio, which is the ratio between the volume of the cylinder when the piston is at the bottom of its stroke and the volume when it’s at the top. This ratio plays a crucial role in determining an engine’s efficiency and power output. Higher compression ratios generally lead to better fuel efficiency and performance but can also increase the risk of engine knock and require higher octane fuel.

The Breakthrough Moment

The turning point for VCR technology came in the late 2010s when advances in materials science, computer modeling, and precision manufacturing finally converged to make the concept viable. Engineers developed sophisticated mechanisms that could alter the position of the crankshaft relative to the cylinder head, effectively changing the compression ratio in real-time.

This breakthrough allowed engines to dynamically adjust their compression ratio based on driving conditions, load, and fuel quality. The result is an engine that can optimize its performance for both high-power output and maximum fuel efficiency, adapting on the fly to deliver the best of both worlds.

How Variable Compression Ratio Engines Work

At the heart of VCR technology is a complex system of linkages and actuators that can alter the piston’s stroke length. By changing the stroke length, the engine can effectively increase or decrease its compression ratio. This is typically achieved through one of two methods:

-

Multi-link systems: These use a series of connecting rods and linkages to adjust the piston’s top dead center position.

-

Eccentric shaft systems: These employ an electronically controlled actuator to change the angle of the crankshaft, thereby altering the piston’s stroke.

Both systems allow the engine to seamlessly transition between low compression ratios (around 8:1) for high-performance scenarios and high compression ratios (up to 14:1) for maximum efficiency during cruising or low-load conditions.

The Performance Paradigm Shift

The implications of VCR technology for automotive performance are profound. These engines can deliver V8-like power when needed, then transition to hybrid-rivaling efficiency during highway cruising. This adaptability means that manufacturers can potentially reduce engine sizes without sacrificing performance, leading to lighter, more nimble vehicles.

Moreover, VCR engines can adapt to different fuel qualities, a significant advantage in markets where fuel standards vary. This flexibility could potentially extend the lifespan of internal combustion engines in an era increasingly focused on electrification.

Challenges and Future Developments

Despite its promise, VCR technology faces several hurdles. The complexity of the system raises concerns about long-term reliability and maintenance costs. Additionally, the added components increase the engine’s weight and cost, potentially offsetting some of the efficiency gains.

However, ongoing research and development are addressing these challenges. Engineers are exploring simpler, more robust VCR mechanisms and integrating the technology with other advanced engine features like cylinder deactivation and variable valve timing.

The Road Ahead for VCR Technology

As VCR engines move from concept to production, their impact on the automotive industry is expected to be significant. Early adopters of the technology have reported fuel efficiency improvements of up to 30% compared to conventional engines of similar output.

The future of VCR technology likely lies in its integration with hybrid powertrains. By combining the adaptability of VCR with electric motors, manufacturers could create ultra-efficient vehicles that offer unparalleled performance and economy.

In conclusion, variable compression ratio engines represent a quantum leap in internal combustion technology. As the automotive world grapples with the transition to electric vehicles, VCR engines offer a compelling bridge technology that could extend the relevance of gasoline engines well into the future. With ongoing development and refinement, VCR technology has the potential to reshape the automotive landscape, offering drivers the best of both worlds: exhilarating performance and exceptional efficiency in a single package.